Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

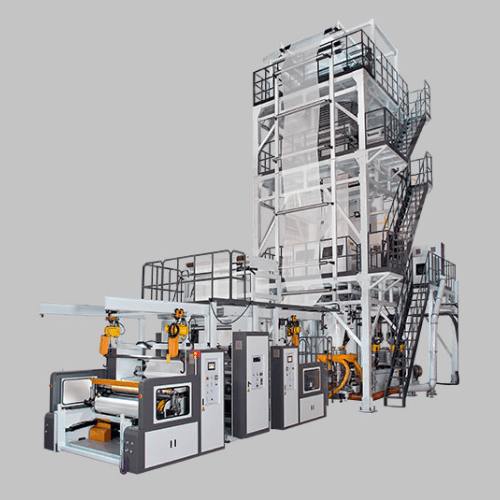

3-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 3-Layer (ABC) PE Group/PP/Recycled 3-Layer Co-Extrusion Blown Film Machine

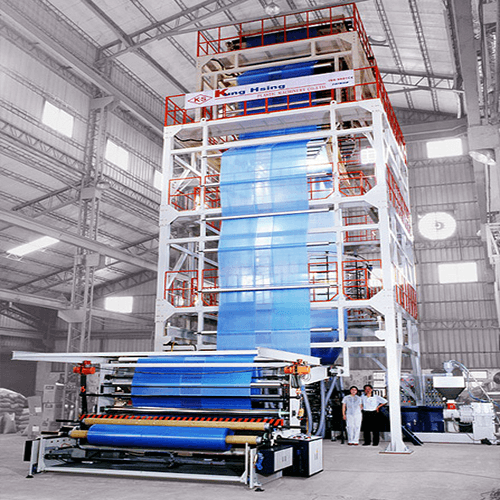

Three-Layer Co-Extrusion For Jumbo Bag (Industrial And Agricultural Use)

Categories : Co-Extrusion Blown Film Machines

THREE LAYER CO – EXTRUSION LINE -- KS – CFLL100 + 120T WITH FLAT FILM WIDTH UP TO 5M, MAX. EXTRUSION OUTPUT 1.1 TONS

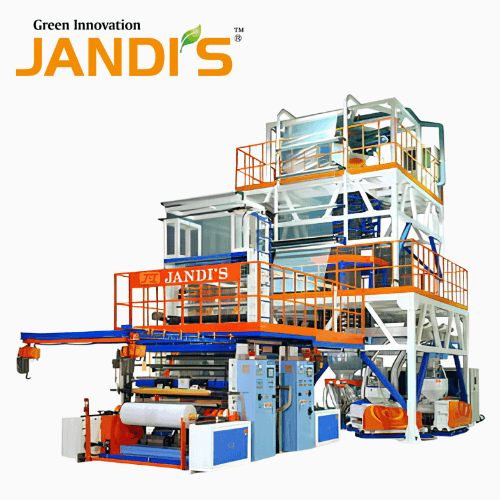

5-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 5-Layer PE Group/Recycled/PA/EVOH 5-Layer Co-Extrusion Blown Film Machine 5-LAYER CO-EXTRUSION BLOW

Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Categories : Blown Film Extruders

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Three-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

THREE-LAYER CO-EXTRUSION Blown Film Machine

LDPE Two Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

Kung Hsing LDPE Two Layer Co-Extrusion

ABA Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

Multi-Layers Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown film production line. Besides, HSIN LONG’s Plastic Film Blowing Machine is customized which depends on characteristics of raw materials and final applications. Before designing the products, HSIN LONG emphasizes on communications and discussion with customers in order to build the reliance with customers. Depending on the use of material, we offer from 3 layers up to 5 layers co-extrusion plastic film blowing machine. Also, the final products have all the desired properties at a significantly reduced cost.

Five-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

3-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 3-Layer (ABC) PE Group/PP/Recycled 3-Layer Co-Extrusion Blown Film Machine